We, the people of Evergreen, have a primary objective of finding a way to use commercial waste and, as much as possible, keep it out of landfills. During our initial audit we will work with you to identify what options are available. Ultimately you have the choice of what you can afford to accomplish based on your time and your objectives when it comes to handling MSW (Municipal Solid Waste). Evergreen is organized to help you around three separate types of common waste: paper and paper derivatives such as cardboard; plastics; and trash that cannot be recycled and must be hauled away to a landfill. The first two of those; paper and plastic can be turned into the raw material to make more paper and plastic things. There is an ongoing demand for those as raw material. There is an open market which may be able to return some value to you. Just for an example, US scrap prices for some common plastics are in the range of $1 – $2 per pound. The third part, MSW, usually is taken to a landfill where you will have to pay to dump it. So there is a clear monetary incentive, not just an environmental one, to recycling as much as you can.

Dealing with plastics

Plastic has been in the news as a major environmental contaminant for years. There is little doubt that we would all be better off if there was an easy way to just melt down plastics and reuse them to make more plastic things. Unfortunately it’s not that simple. Because plastics come in different types, sizes and shapes, the machinery to handle plastic waste in bulk can only process certain types. And if your plastic doesn’t meet the rules then it will end up in the trash. So the first step in recycling plastics is to understand what can and what cannot go to the local plastics recycler. Evergreen can help with this and we can also provide recycle bins to help with sorting the “good” plastics, from the “bad” plastics.

Plastic has been in the news as a major environmental contaminant for years. There is little doubt that we would all be better off if there was an easy way to just melt down plastics and reuse them to make more plastic things. Unfortunately it’s not that simple. Because plastics come in different types, sizes and shapes, the machinery to handle plastic waste in bulk can only process certain types. And if your plastic doesn’t meet the rules then it will end up in the trash. So the first step in recycling plastics is to understand what can and what cannot go to the local plastics recycler. Evergreen can help with this and we can also provide recycle bins to help with sorting the “good” plastics, from the “bad” plastics.

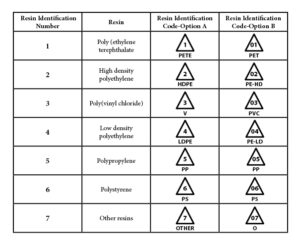

Each plastic is made of a specific resin. Each resin is given a resin number which is embossed or printed on the product usually on the bottom. The plastic types are numbered 1 through 7 with the number 1 being the easiest to recycle and number 7 the hardest. You can see a table to the right which names each of the resin types. These are the terms that recyclers use for the type of plastic that was used to make the object you are recycling. Just as an example I looked up the recycling rules for a company in the Ft. Worth area and this is how they describe one of their requirements: A Grade. Post consumer material that consists of 95% clean, dry, clear natural LDPE film. Minimal amount of HDPE. So the LDPE film is number 4 and the HDPE is number 2. Both have to be clean dry and clear, not wet, dirty, or with a color tint added. So these might happen to be typical bags that you would find in the grocery store for holding fruits or vegetables, though more HDPE is being used than LDPE these days. Obviously as a business it probably doesn’t warrant using this product to initiate a recycling program, but as a consumer it’s good to know that they can be recycled locally and if your local grocery store recycles these bags (and many do, now) you know where you can dispose of them and that they will be processed locally. This is just an example but at Evergreen it’s our business to know the local requirements of various recyclers and when we set up your programs we look at ways to optimize your return for recyclable goods.

paper prospects

Paper happens to be one of the more successful recycle stories. A very high percentage of paper is already getting recycled. Again, looking within the Ft. Worth metropolitan area there are several companies that handle paper products for recycling. It does help if similar paper types (card stock, printer paper, corrugated cardboard) can be aggregated, but it is not always necessary, Again Evergreen will advise you of the most economical solutions for your objectives consistent with the paper mill’s requirements. One thing that all paper recycling mills agree on is that paper recycles best when it is clean, dry and not heavily dyed or printed. Very often the goal of preparing paper products for transport to the paper mill is to make them as compact as possible. Evergreen has balers that can be used on-site to compress cardboard into rough “cubes” that can be stacked and secured for transport. Evergreen also maintains a fleet of trucks (Flatbed, Tractor Trailer and Roll-Off) as well as dumpsters to use with a Roll-Off Truck. These trucking options allow us to handle various types of waste in different size lots. They also allow us to combine loads when it makes sense to meet minimum weight requirements for paper recycling mills or plastic recycling facilities.

Paper happens to be one of the more successful recycle stories. A very high percentage of paper is already getting recycled. Again, looking within the Ft. Worth metropolitan area there are several companies that handle paper products for recycling. It does help if similar paper types (card stock, printer paper, corrugated cardboard) can be aggregated, but it is not always necessary, Again Evergreen will advise you of the most economical solutions for your objectives consistent with the paper mill’s requirements. One thing that all paper recycling mills agree on is that paper recycles best when it is clean, dry and not heavily dyed or printed. Very often the goal of preparing paper products for transport to the paper mill is to make them as compact as possible. Evergreen has balers that can be used on-site to compress cardboard into rough “cubes” that can be stacked and secured for transport. Evergreen also maintains a fleet of trucks (Flatbed, Tractor Trailer and Roll-Off) as well as dumpsters to use with a Roll-Off Truck. These trucking options allow us to handle various types of waste in different size lots. They also allow us to combine loads when it makes sense to meet minimum weight requirements for paper recycling mills or plastic recycling facilities.

To learn more about Evergreen Recycling and their recycling and waste management programs visit their web site at https://evergreen-recycling.com/plastics-recycling/

You can also reach out to them directly through this contact link https://evergreen-recycling.com/contact/ or give them a call at (817) 293-4400