THE BASICS OF BALING

At some point within your company’s recycling plan it may grow to the point that it makes sense to deliver recyclable bales of waste paper products instead of a bin of loose recyclable product. Baling makes the recycled product more compact and easier to handle for the recycling entity. Baling consists of compacting the recyclable material and then securing its compacted, rectangular shape by holding the compacted material in place with a series of loops of baling wire. It also means that you will not have to schedule the recycling hauler quite as often. You’ll be sending fewer, but heavier and more compact loads.

TO BUY OR LEASE A BALER?

Waste management companies, like Evergreen Recycling, may have an appropriate baler available for lease. Generally speaking, if you go this route, then they will match your needs with the right product and then train your staff how to use the baler properly. They will also handle any maintenance or repair issues. Basically they will teach you all you need to know about proper operation of the baler.

Aside from the benefits mentioned above about fewer trips to pick-up your commercial paper waste, there is the benefit that the bales can be easily stacked and secured on a flatbed truck. Otherwise a tractor trailer would need to be used, which would cost more to load and unload. Though a tractor trailer can handle baled waste, a flatbed is preferred for stacked, baled waste.

WHAT GOES INTO THE WASTE PAPER BALE?

Though we think of commercial paper as printed paper stock, flyers, posters, documents, reports, and such, that is not always the case. A lot of recycling facilities are now set-up to handle so-called mixed recyclables. If you know that your waste is going to a mixed recycling center then you may be able to include corrugated cardboard, paperboard cartons, plastic water bottles, jugs, clear plastic cups, aluminum beverage cans, clean aluminum foil and even clean jars and bottles. When properly included, these boost the value of the recycled bales and can result in a larger rebate.

WHAT WASTE MUST STAY BEHIND?

Although recycling has a come a long way over the last 50 years or so, it still is not perfect. The variety of wasted that gets created often consists of a wide variety in types of plastic, paper glass and metal. As a result we are faced with being more knowledgeable about how to optimize our recyclables and minimize the amount of waste going to a landfill. The answer is complicated by the fact that some seemingly east-to-recycle items, in fact must go to a landfill as there is no economical way to process it for re-use. Here’s an example: A clear plastic drinking cup can be recycled, however the lid and the plastic straw that came with the cup must go into the trash. This requires a little bit more work in sorting the waste before baling. It’s worth the little bit of extra work, because, if that cup lid or straw is incorporate into a waste bale, the operator at the recycle plant will have to divert the entire bale to the landfill. They just can’t economically pick through bales of waste and pull out the unrecyclable waste product.

LOCAL KNOWLEDGE IS KEY

As you can see the basic principle of recycling is very doable. If you identify a large enough quantity of waste streams that are recyclable, it may be worthwhile to bundle your waste into bales. And, in some communities, mixed recycling is allowed, which both simplifies some waste handling and complicates some other types of waste.

Setting up and operating a waste management system is best done through a local provider, due to the variation in local facilities’ ability to handle certain types of waste. The process of setting up a waste management program starts with a free audit. Evergreen Recycling can take the audit results and turn that into a plan to save you money on your waste handling costs and, in some cases even generate an income stream based on rebates for your recycled materials.

MAKE A POSITIVE DIFFERENCE

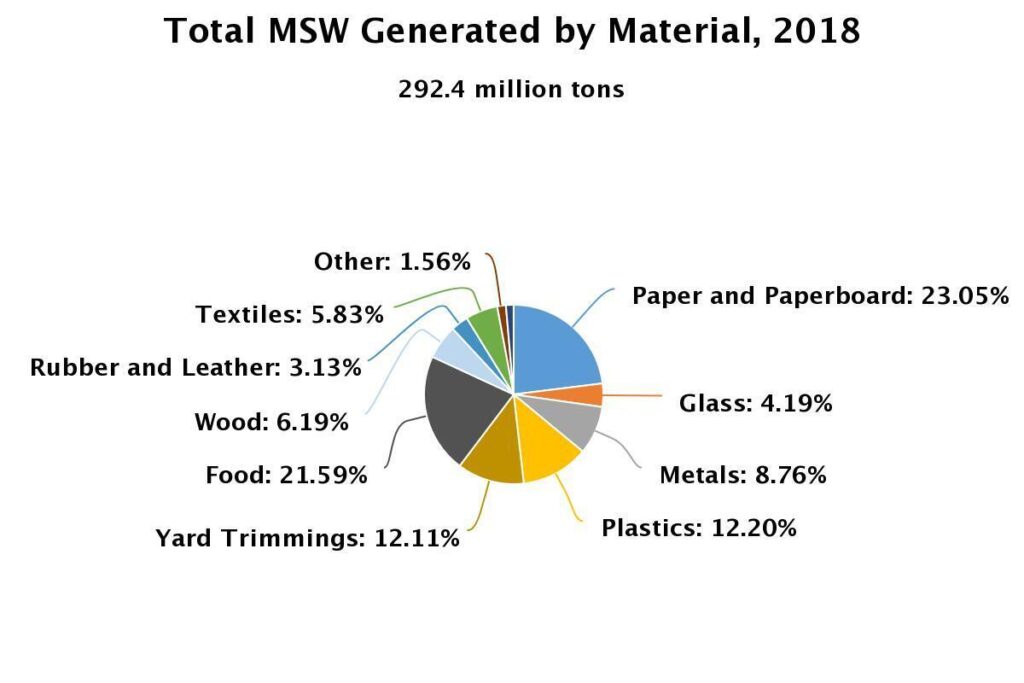

According to the US EPA ( https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials#Generation ) over 290 million tons of solid waste were produced annually in 2018 (most recent numbers.) Paper Waste, although declining due to the increase digitizing of information, leads the pack at 23% of the total. Plastic, metal, and glass combined are about the same as paper in turn of tonnage. However plastics are notable for their longevity in the environment with the added observation that the variety in plastics makes them more difficult to recycle due to their sortation requirements.

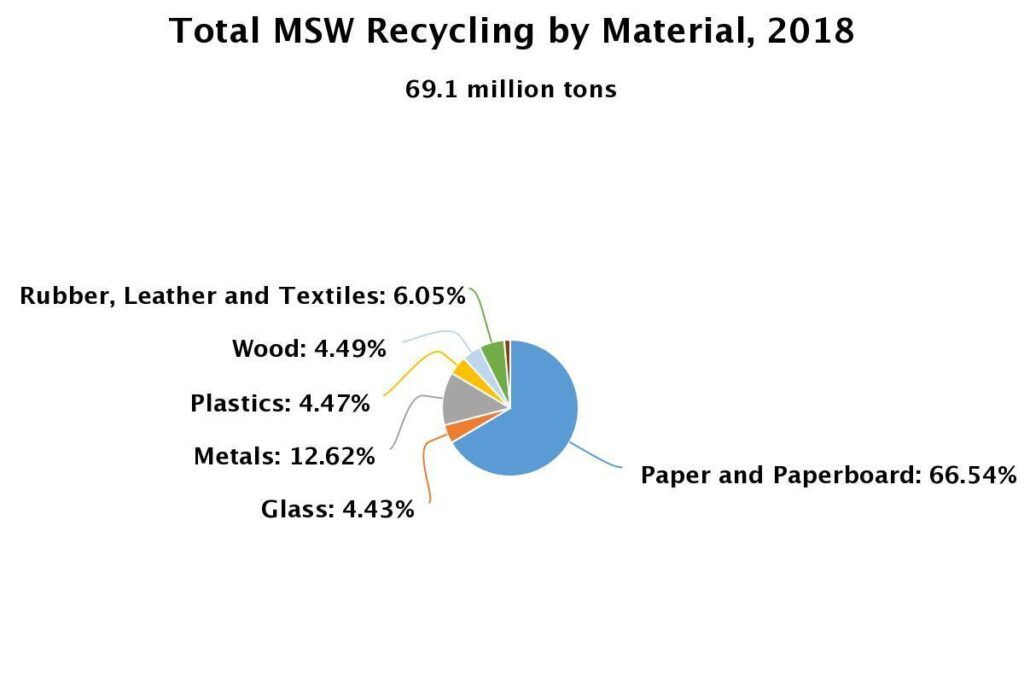

This begs the question. If we are generating nearly 300 million tons of Municipal Solid Waste (MSW), how much are we recycling? It turns out that the answer is about 70 million tons. Or just under ¼ of the total. And of that nearly 70 million tons Paper and Paperboard are about 2/3 of the total tonnage. It’s a good time to start your own paper recycling program. From the EPA data, paper and paperboard are the most successfully recycled waste in the US. On top of that, as we’ve seen in several cases, certain municipalities allow for plastics, metal, and glass to be added in with mixed recycling programs, so you can even get more value back for your investment in these programs.

Consider setting up a bundled recycling program and reach out to the Evergreen Recycling Company. It all starts with a simple, free audit and then you’ll know your options. And remember, their service includes:

- Signed Receipts so you can monitor volumes

- Monthly volume reports

- Monthly pricing letters that identify market changes

- Prompt payment schedules

- Certified truck scale records that ensure proper weights

To learn more about Evergreen Recycling and their plastic recycling and waste management programs visit their website.

You can also reach out to them directly through this contact link.

or give them a call at (817) 293-4400