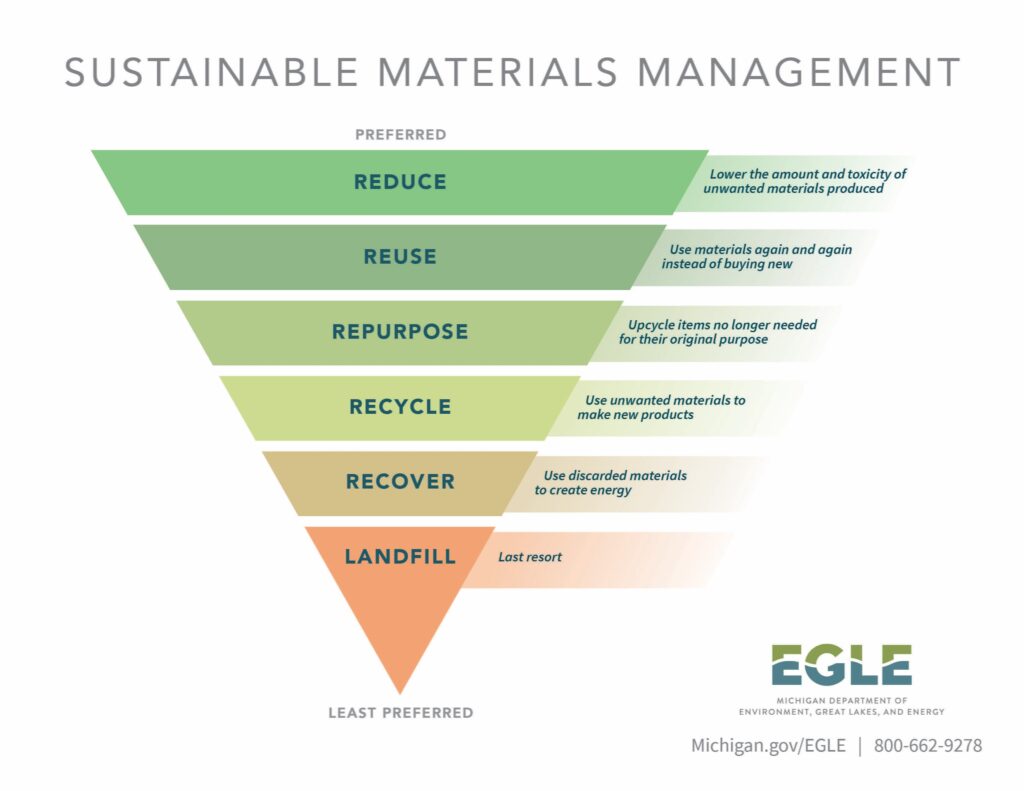

It’s not a given fact that the cost of landfills will always be climbing. Nonetheless this has been the trend for many years and it is instructional to understand what factors control the cost of landfill construction and operation. Starting at the most basic level, there is a hierarchy for waste (also known as Municipal Solid Waste or MSW) as illustrated by the waste ‘funnel” shown at the right. The highest priority in reducing waste (and therefore cost) is by reducing the amount of waste that is created in the first place. Second is to reuse wherever possible and so on with landfill being the activity of last resort. So, the major controlling cost in general is how well people and businesses are able to accomplish these pre-landfill steps. Even very dedicated municipalities rarely exceed 30% of waste recovery overall, meaning some 70% or more ends up in a landfill. Unless this changes dramatically, the demand for landfills will continue to rise. Another contribution to landfill costs is that up until 2018, China was importing MSW from the US and other large waste producers. When China stopped these importations, waste ended up being redirected to Thailand, Vietnam, and Malaysia. Of course some also was directed back to US landfills, all of which increased the cost due to the increasing demand and a supply that was proportionally, too small.

It’s not a given fact that the cost of landfills will always be climbing. Nonetheless this has been the trend for many years and it is instructional to understand what factors control the cost of landfill construction and operation. Starting at the most basic level, there is a hierarchy for waste (also known as Municipal Solid Waste or MSW) as illustrated by the waste ‘funnel” shown at the right. The highest priority in reducing waste (and therefore cost) is by reducing the amount of waste that is created in the first place. Second is to reuse wherever possible and so on with landfill being the activity of last resort. So, the major controlling cost in general is how well people and businesses are able to accomplish these pre-landfill steps. Even very dedicated municipalities rarely exceed 30% of waste recovery overall, meaning some 70% or more ends up in a landfill. Unless this changes dramatically, the demand for landfills will continue to rise. Another contribution to landfill costs is that up until 2018, China was importing MSW from the US and other large waste producers. When China stopped these importations, waste ended up being redirected to Thailand, Vietnam, and Malaysia. Of course some also was directed back to US landfills, all of which increased the cost due to the increasing demand and a supply that was proportionally, too small.

LANDFILL CONSTRUCTION AND OPERATION

If we move our focus from the global factors causing rises in landfill costs and look into regional factors, consideration should be given to the cost of construction and operation of a landfill. Landfills rely on low permeability clay, sand, plastic sheeting, piping and fill dirt to collect liquid waste (leachate) and gases (methane and CO2, also called landfill gas or LFG). Finding a piece of land that has all of the right attributes and developing it to be useful as a landfill space, including proximity to the natural resources (clay and sand) and availability via roadway is difficult. A lot of the most desirable areas are already claimed or are near their end of life. This pushes the landfill access to areas that are farther away from city centers and increases transportation costs.

Studies indicate that an average cost to set up a landfill operation is about $500,000 per acre, exclusive of any onsite buildings. Additional construction work to build supporting structures could add $1.5M to the set-up cost and annual operating costs would run about $600,000 per year. A 200 acre site for example would cost $100M+ to set-up and at least $600K for annual operations. Landfills are intended to operate for about 30 years, then they will be capped off (another $200,000 per acre) and monitored for another 30 years (at about $100,000 per acre). The landfill operator needs to ensure that at the time of closure they will have the necessary operational resources to support this 30 year monitoring period.

PAYING FOR LANDFILLS

There are two common ways to pay for a landfill: either tipping fees, or taxes. Generally speaking, privately operated landfills rely more heavily on tipping fees while publicly owned landfills rely on taxes, although either pubic or privately owned facilities can be funded by a combination of tipping fees and taxes. Private landfills tend to be larger and to serve a wide region. This gives them some economy of scale and, depending on competition their tipping fees will be competitive. Public landfills, paid for mostly by taxes generally have the flexibility to direct some of their revenue toward non-landfill activities, such as recycling programs.

The same market forces that support the trend toward larger and privately held landfills, have also driven these operations toward alternative revenue strategies. One common one is to install weighing equipment and charge per ton as opposed to charging per load (weight instead of volume). A load of scrap metal would create more revenue than a load of miscellaneous household waste for example. Some landfills have opened themselves up to landfill mining contracts where a second party has access to the landfill to recover the precious metals in electronics or aluminum waste for example. Still other operators look toward generating carbon credits by burning off the methane portion of the LFG generation in the landfill, or using the waste heat for energy generation. Both are a potential source of revenue for as long as 60 years.

THE FUTURE OF LANDFILLS

Most of the same aspects of the market for MSW are expected to continue into the near future.

To summarize these market drivers:

- To achieve economies of scale, larger regional landfills handle the majority of MSW.

- More remote and larger landfills potentially require longer trips which can drive up transportation costs, dependent on the price of fuel

- Municipalities are reluctant to make the large capital investment that private companies can justify based on cash flow stretching across generations.

- Large privately run landfills have no incentive to reduce the flow of MSW

- Private landfills are incentivized to find alternative revenue streams such as producing power out of LFG, generating and selling compost, even leasing mining rights to opportunistic mining companies.

- The world population will continue to grow and that means more waste (minus any benefit from the mitigation strategies mentioned at the beginning of this article).

None of these activities, in and of themselves necessarily creates a higher cost per ton for operations. However if we look at the industry consensus for the five years ending in 2021, the average cost per ton in tipping fees at that time was projected to increase from $50.30 to $53.53 which is a 6.4% increase on a nationwide basis. Actual data, taken more recently agrees very closely with these numbers. Some regions have seen as much as a 10% increase over this period. The fact is, that costs continue to rise and there is no “silver bullet” that would reduce the waste problem significantly or reduce the cost of handling solid waste. However, looking back at the funnel from the beginning of this article, if any one of the strategies of reduce, reuse, repurpose, etc. can be successfully implemented, it will ultimately reduce the remaining amount available for landfills by reducing the total amount of MSW overall.

To learn more about Evergreen Recycling and their recycling and waste management programs visit their web site at: Evergreen Web Site

You can also reach out to them directly through this contact link: Contact Evergreen or give them a call at (817) 293-4400